SERVICE

What is MIM?

Metal powder injection moulding (MIM) is a metal manufacturing method in which a material called feedstock—a mixture of metal powder and a binder made of resin, wax, or other substances—is injected into a mould and then sintered. This process, known as MIM manufacturing, enables efficient production of complex metal components that are difficult to create using conventional methods. By utilizing MIM manufacturing, manufacturers can achieve both precision and scalability in producing metal parts.

MIM process

MIM Features

| Conventional MIM | Additional feature by μ-MIM® | |

|---|---|---|

| Material |

|

|

| Design |

|

|

| Injection moulding |

|

|

| Sintered body |

|

|

Accuracy and specifications

| Conventional MIM | μ-MIM® | ||

|---|---|---|---|

| Material | Length | <50mm |

<10mm Maximum 30mm in one direction |

| Thickness | 0.5~5mm | ||

| Minimum wall thickness | 0.3mm(partial) | 0.1 mm (6mm square) | |

| Smallest hole size | 0.3mm(partial) | Φ0.03mm | |

| Tolerance | < 5mm | +/- 0.03mm | +/- 0.01mm |

| 5-10mm | +/- 0.04mm | +/- 0.03mm | |

| 10-20mm | +/- 0.08mm | ||

| 20-30mm | +/- 0.15mm | ||

| Relative density(%) | 95-98 | > 98.5 | |

| Surface roughness (Ra) | < 3μm | 0.3μm(In case of applying ultra fine powder) | |

| Rmax | < 10μm | 2~10μm | |

| Product weight | < 50g | ≦ 10g | |

What is μ-MIM®?

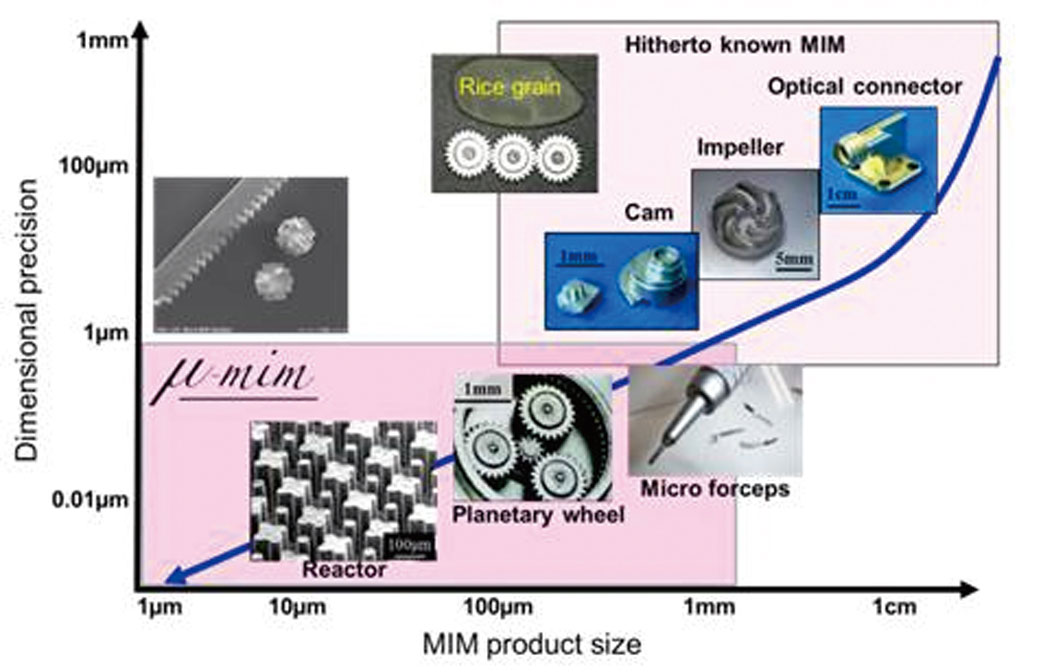

μ-MIM® is an advanced technology in MIM manufacturing that enables the production of ultra-precise MIM components. This technology focuses not only on miniaturizing product size but also on ensuring high accuracy and quality.

μ-MIM® meets the following demands in MIM manufacturing:

- ・Mass production of components and materials that are difficult to machine

- ・Integration of small components that are difficult to assemble

- ・Mass production of components with size and tolerance requirements that are challenging in conventional MIM manufacturing

- ・Adding value to components by integrating multiple functions

In conventional MIM manufacturing, most parts range from several millimeters to several centimeters and must satisfy dimensional tolerances of about 5–10% of the part size. With μ-MIM®, even smaller products with stricter tolerances can be mass-produced, overcoming the limitations of standard MIM manufacturing.